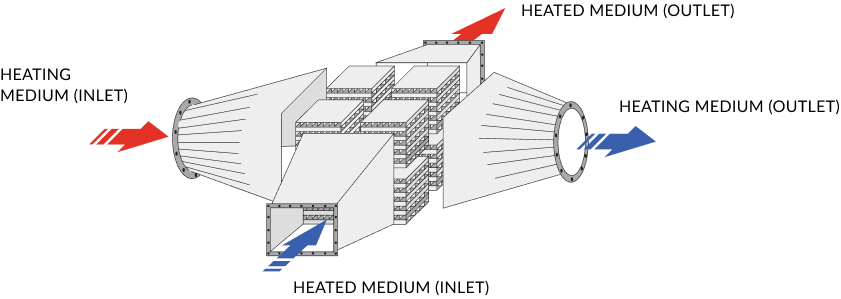

Industrial recuperators are designed to heat of air by flue gases, waste heat and similar types of mediums.

Heated air can be used as a combustion air for increasing efficiency of burning processes.

Recuperators are usually used together with furnace equipment in metallurgy, oil and gas industries etc.

At Termo-Nord Stream we offer the following: