Our gas-liquid heat exchangers are highly efficient and have several advantages.

Our gas-liquid heat exchangers are highly efficient and have several advantages.

Our heat exchangers are compact and of low weight though have large heating surfaces, which result in maximum efficiency. So, often they can be installed in places where common heat exchangers can not fit.

Installation, maintenance and repair (if necessary) of our heat exchangers are simple and easy to handle. Heat exchangers are self-cleaned and will require cleaning only when they are not properly used.

Operate in aggressive environments.

Mechanical shocks, vibrations, and thermal shocks do not affect efficiency of air preheater.

Steel grade for gas panels is selected depending on the requirements and operating conditions.

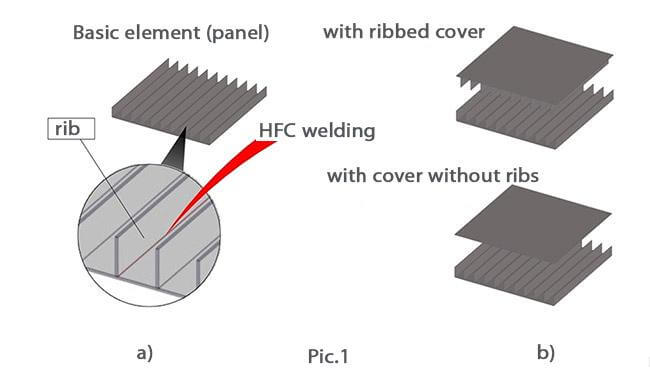

Fluid panels also have ribs that are designed to cut a single stream into several streams. This ensures maximum liquid contact with the surface of the panel, increases the flow rate and increases the heat transfer coefficient.

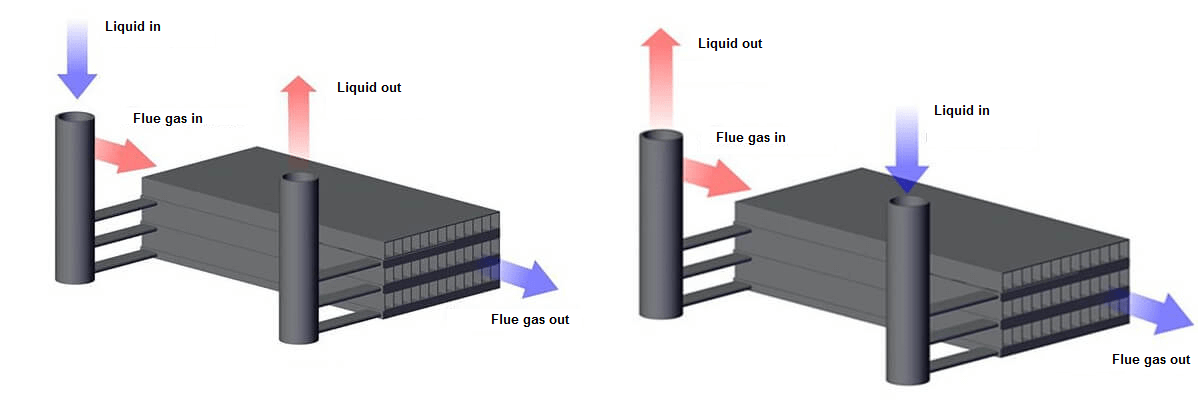

Gas and liquid movements in the heat exchangers.

When order a heat exchanger it will be necessary to specify the conditions in which it will operate. Our specialists will choose a suitable steel grade for the panels.

Full comply with technical requirements and payback period

2 years warranty

Patents for equipment and quality assurance

Production and design of turnkey heat exchangers

20 years on the market, we produce more than 70 heat exchangers per year

Free consultation to find the best solution