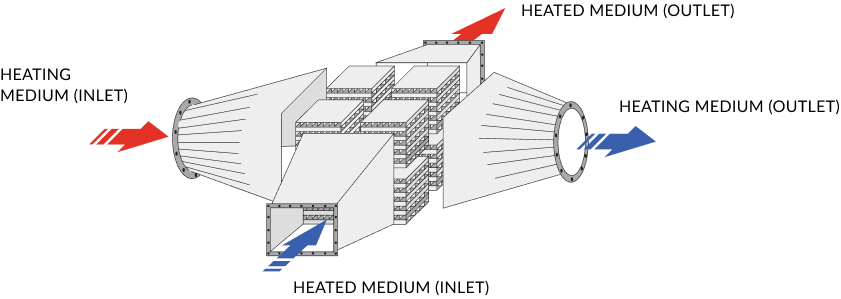

The heat exchangers Gas-gas and Gas-air are usually used to heat the incoming streams of air by flue gases, steam or similar medium.

Heated air or gas can be used to increase efficiency of production processes or to maintain temperatures in premises.