Air coolers function as the heat transfer units that simultaneously heat incoming air and cool output gases. So, heated air can be used for production purposes while output gases are chilled and give less heat to the atmosphere.

Air coolers function as the heat transfer units that simultaneously heat incoming air and cool output gases. So, heated air can be used for production purposes while output gases are chilled and give less heat to the atmosphere.

Lower weight and smaller size — 2-8 times less than conventional heat exchangers.

Easy to transport, install, maintain and repair.

Operable in aggressive conditions.

Possible to clean and self-clean gas-air ducts from the combustion products.

Easy access to each module during installation, repair and inspection.

Apply appropriate steel grades for different parts of heat exchanger.

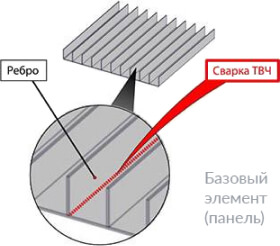

Ribbed plate gas coolers, which belong to the new generation equipment, will most effectively handle the double task. Operating principle is based on cross-motion of gas medium, and special steel panels with a ribbed surface serve as a heat-transferring element. Gas and air flow travel in perpendicular directions relative to each other through a module that consists of the panels.

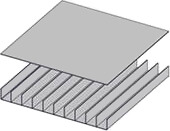

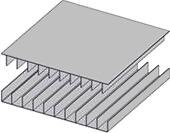

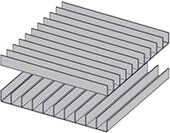

A set of basic panels forms an element of the module:

In the first and second option, spacers are installed between the panels so that they create the next channel with the transverse direction of the medium flow.

In case of high temperatures with rapid steel heating, thermal stresses may occur. Ribbed plate coolers have high thermoplasticity, so stresses do not cause destruction of the unit, resulting in a long operational life.

Full comply with technical requirements and payback period

2 years warranty

Patents for equipment and quality assurance

Production and design of turnkey heat exchangers

20 years on the market, we produce more than 70 heat exchangers per year

Free consultation to find the best solution